Pattern shop

Is engaged in the development, design and manufacture of model equipment from epoxy plastics, wood, aluminum and expanded polystyrene.

Engineers-modelers work in CAD-programs on CNC-centers and make model equipment for manual and machine molding of various series.

Form-preparatory department

At the enterprise there are two ways of making forms:

1. Furanprocess

Formation of XTC-process based on furan resins takes place on English machines "Omega" with a capacity of 10 and 15 tons per hour. All forms are coated with a non-stick coating on an alcohol basis using watering, spraying and mechanical coating. This process provides high dimensional accuracy and high-quality external surface of the castings.

Forming machine "Spartan"

Forming machine "Spartan"  The form is ready for casting

The form is ready for casting  The regeneration of the used mixtures is carried out by Sand Mold, USA, which ensures the recycling of 90% of the molding mixture

The regeneration of the used mixtures is carried out by Sand Mold, USA, which ensures the recycling of 90% of the molding mixture 2. Machine molding

Manufacture of classic sand and clay molds of hydraulic pulse shaping on the HEINRICH WAGNER SINTO HSP2 machine with a flask size of 800x600x300 mm (and also on the SAVELLI machine). The advantages of this type of molding are high dimensional accuracy, no displacements, minimal foundations, high hardness of the mold. The molding mixture is made at the automatic station WEBAC.

Molding machines ensure the production of European quality castings of European quality

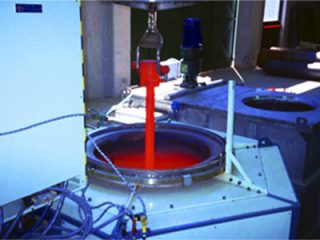

Melting department

Equipped with crucible induction steelmaking furnace Inducotherm 2x2 tons. In this type of furnace, carbon steels, low- and high-alloy steels, manganese steels, low-alloy and high-alloy cast iron, as well as high-strength, with vermicular graphite, copper and aluminum alloys are melted.

Inducotherm is a proven manufacturer of world-class casting furnaces

Inducotherm is a proven manufacturer of world-class casting furnaces  Each of the inductors melts up to 2,800 kilograms of metal

Each of the inductors melts up to 2,800 kilograms of metal  The temperature of the liquid metal when discharged from the furnace before pouring into the mold is measured by the contact thermocouple Heraeus and before filling it is controlled by an optical two-channel pyrometer Aircon,UCA

The temperature of the liquid metal when discharged from the furnace before pouring into the mold is measured by the contact thermocouple Heraeus and before filling it is controlled by an optical two-channel pyrometer Aircon,UCA Blow out and thermal separation

It is equipped with crushing chambers and thermal furnaces with a mobile hearth in size 4.5x2.6x1.6 meters, as well as shaft type furnaces and calculating basins with a volume of 120 and 30 m3 of water.

1. Branch of stump and cleaning

Shot blasting is carried out in the Wheelabrator, Stem up to 2500x1500 mm

Shot blasting is carried out in the Wheelabrator, Stem up to 2500x1500 mm  In the fractional process, a fraction of 1.8-2.2 mm is used

In the fractional process, a fraction of 1.8-2.2 mm is used  The equipment is set to clean both large and small castings

The equipment is set to clean both large and small castings

Casting is done manually

2. Heat treatment department

They are equipped with chambers and thermal furnaces with an outbuilding site measuring 4.5x2.6x1.6 meters, as well as shaft type furnaces and hot water tanks with a volume of 120 and 30 m 3 .

A thermal furnace measuring 4.5x2.6x1.6 meters with an approximate loading of 15 tons.

A thermal furnace measuring 4.5x2.6x1.6 meters with an approximate loading of 15 tons.  Hardening of products is carried out in water pools with a volume of 120 m3 with artificial flow

Hardening of products is carried out in water pools with a volume of 120 m3 with artificial flow  The furnace heats the castings to a temperature of +1180 °C

The furnace heats the castings to a temperature of +1180 °C  A shaft furnace for rolling parts up to 2800 mm long ensures that there is no warpage

A shaft furnace for rolling parts up to 2800 mm long ensures that there is no warpage Laboratory

Performs rapid analysis of the chemical composition of raw materials, materials, melted metals and alloys on the emission spectral analyzer Solaris CCD Plus (Italy), Argon 5. Analysis and testing of molding mixtures and mold hardness. Hardness testing of finished castings by the Brinell and Rockwell method. Mechanical properties are tested on a tensile machine ZD 10/90. The microstructure is controlled by a microscope. The characteristics of the castings are recorded in the product quality certificate.

Emission spectral analyzer Solaris CCD Plus

Emission spectral analyzer Solaris CCD Plus  Mini-thermo-furnace determines the thermal stability of alloys

Mini-thermo-furnace determines the thermal stability of alloys  Control of the tensile strength of the product

Control of the tensile strength of the product  Checking the product for defects

Checking the product for defects