Western Foundry Group

Western Foundry Group is a powerful association of two modern production sites: Promlit Plant LLC and Gorstal Plant LLC. Our enterprises are located in the border region of western Ukraine, just 20 km from the Polish border, which provides convenient logistics for European partners.

We offer a full cycle of casting production – from model design to machining of the finished part. The use of green energy (a 5 MW solar power plant and 10 MW of batteries) allows us to reduce our environmental footprint and meet modern requirements for sustainable production.

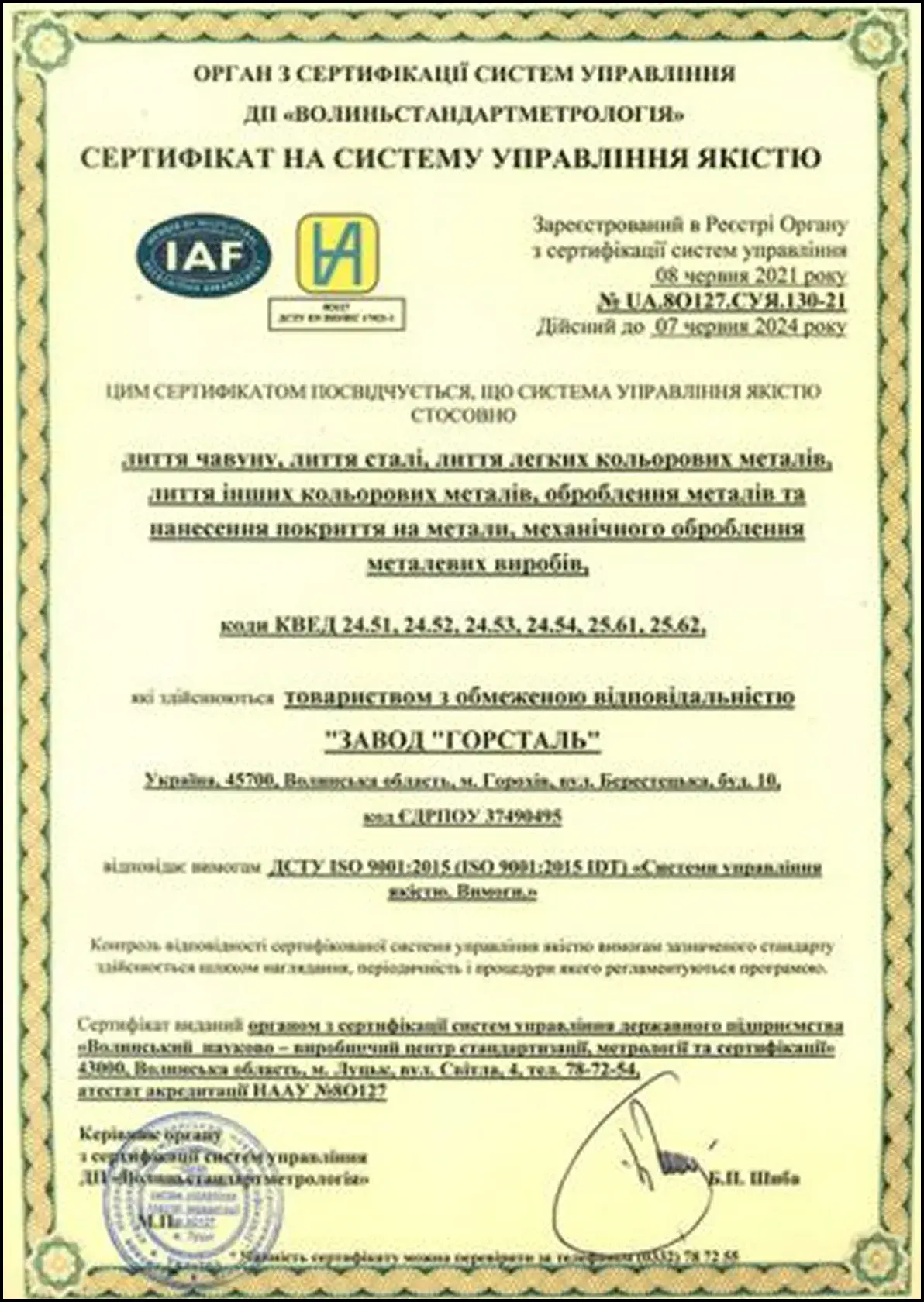

Our focus on European quality standards, ISO 9001:2015 certification and modern equipment fleet ensure a stable partnership with customers from the EU, the Balkans and Eastern Europe. Our mission is to produce high-quality steel and cast iron castings with specified physical and mechanical characteristics and complex geometry that meet all customer engineering requirements.

Promlit and Gorstal Plant

"Promlit" Plant

"Gorstal" Plant

Main production capabilities

-

Full production cycle

We provide a full production cycle – from creating a 3D model and designing tooling to casting, machining and heat treatment, quality control and delivery of finished products. This allows us to fully control the quality at every stage and respond promptly to customer needs.

-

Great flexibility

Our equipment allows us to fulfill both small and medium-sized batches and unique, individual orders. We can work with parts weighing from 3 kg to 15 tons and up to 8 meters long.

Materials

We work with a wide range of materials, which allows us to optimally match the alloy composition to the specific operating conditions of the part. We use gray and ductile iron, carbon, alloy, heat-resistant, acid-resistant and wear-resistant steel, as well as Hatfield steel for castings.

We cooperate with various industries

Mechanical engineering

Manufacturing of body parts, frames, bases, brackets, components and mechanisms for various machinery and equipment.

Mining industry

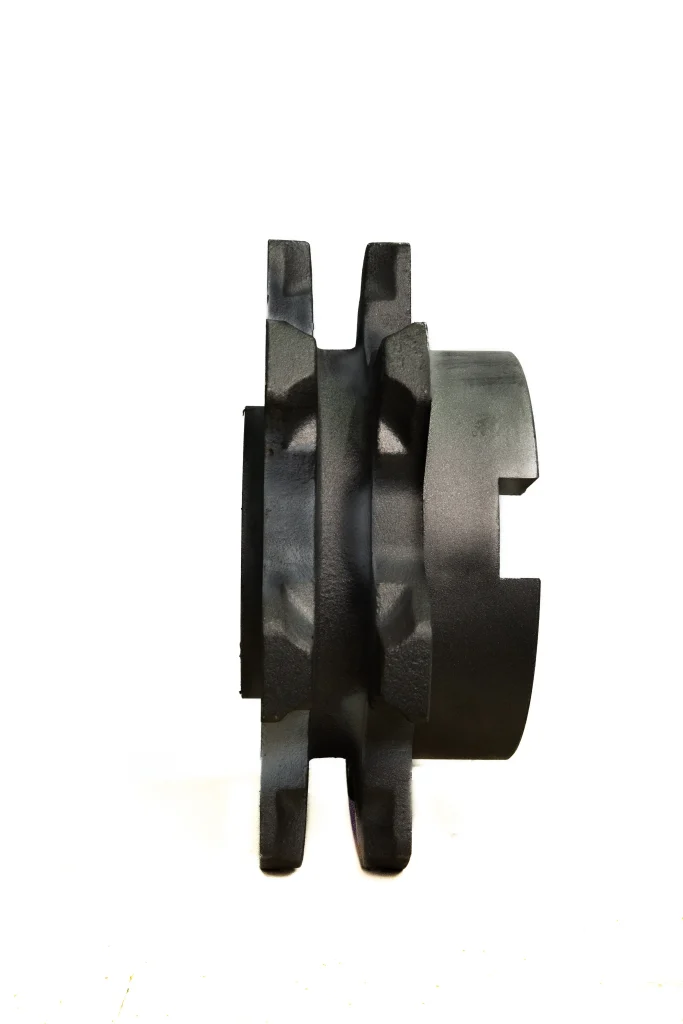

Production of parts for scraper conveyors, mining machines, drives, buckets, spare parts for crushers and other parts for mining equipment.

Chemical and oil and gas industry

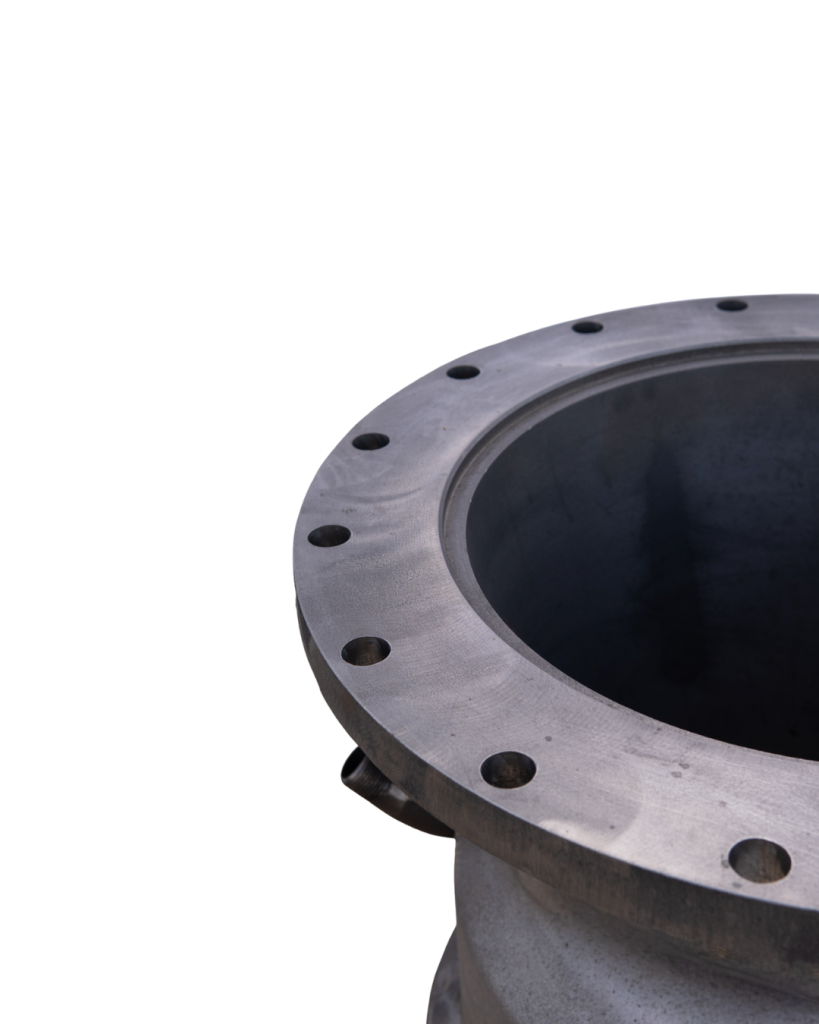

Manufacturing of parts resistant to aggressive environments: pump housings, valves, pipeline elements, flanges, reactors.

Metallurgy

Castings for metallurgical units, foundries, furnaces, lifting mechanisms, and conveyors.

Construction and infrastructure

Production of slabs, bases, supports, components for bridges, ventilation grilles, manholes, covers, ladders and other structural elements.

Water supply and sewerage sector (WSS)

Valve bodies, gate valves, flanges, grilles, hatches, water and heat supply wells.

About us in numbers

-

20 +hectares

Common production area

-

1000 + tons

Castings per month - total capacity of the group

-

300 + satisfied customers

From the EU, the Balkans and Eastern Europe, and the United States

Plant photo gallery

Equipment

-

Automatic molding lines

Savelli’s modern automatic lines with mold sizes of 1250x1000x300x300 provide high productivity and accuracy in the production of castings with complex geometry.

-

Manual molding with Alpha-Set technology

Alpha-Set technology is a modern manual molding method used to produce castings with complex or large shapes, as well as for small batches or individual orders. This technology enables the production of parts that cannot be realized on automatic lines with maximum precision and surface quality.

-

Model tooling production area

Our in-house modeling department is equipped with 3- and 5-axis machines up to 8000 mm, which allow us to quickly produce complex models, templates and casting tooling. Manufacturing large-sized elements with maximum precision is one of our key advantages.

-

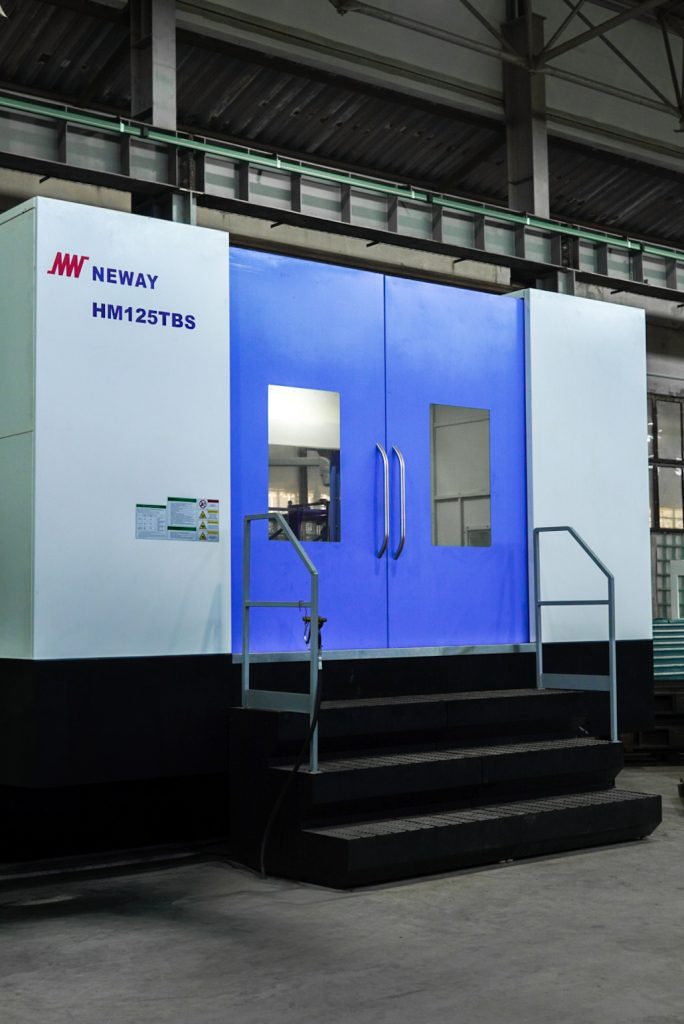

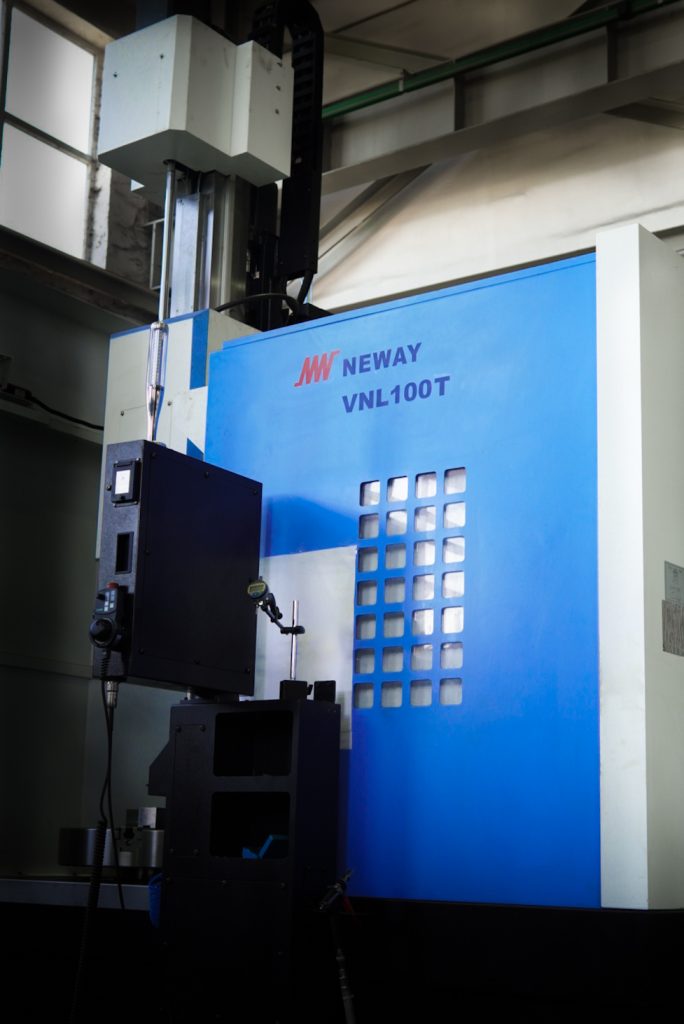

Modern turning and milling CNC machining centers

We have a fleet of high-precision turning, milling, grinding and multifunctional centers, including 5-axis CNC, gear tapping, hobbing and grinding machines for complex machining of parts of any complexity.

Additional features

-

Heat treatment (quenching, normalizing)

Provides specified mechanical properties and metal structure.

-

3D scanning

For precise geometry measurement and control of finished product conformity to drawings.

-

In-house laboratory

Spectral, chemical, mechanical, metallographic analysis, testing of mixtures and finished products.

Energy independence and environmental friendliness

We have invested in our own energy sources

Solar power plant with a capacity of 5 MW

Storage batteries for 10 MW

Perevagi of our production capacities

-

Flexibility and efficiency in fulfilling orders of varying complexity

Our production lines and process organization allow us to respond quickly to any customer request – from single prototype production to serial batches. We can easily adapt to changes in technical specifications, specifics of drawings or materials, ensuring timely and accurate execution of even the most non-standard projects.

-

High level of automation and accuracy

Modern equipment, Savelli automatic molding lines and 3- and 5-axis CNC centers guarantee the accuracy of the geometry of each part and minimize the human factor. Automation ensures consistent quality, repeatability of parameters in serial batches and efficient production of even the most complex products.

-

Ability to produce large and complex castings

Our production facilities allow us to work with castings weighing from 3 kg to 15 tons and up to 8 meters long. This allows us to take on complex, large-sized and customized projects for the energy, machine building, heavy industry, transportation and other sectors.

-

Focus on the requirements of European standards and individual specifications

We operate in accordance with the ISO 9001:2015 certificate, EN and DIN standards. Each project is tailored to the customer’s requirements: from the selection of materials and casting methods to the preparation of an individual process map that takes into account the operating conditions and the customer’s wishes.

-

Full cycle of quality control - from raw materials to shipment of finished products

The company has its own laboratory with modern equipment at all stages of production. Control includes: rapid chemical composition analysis, spectral and mechanical testing, metallography, 3D scanning, capillary and magnetic particle inspection. This ensures consistent quality of each batch and compliance with European and industry standards.

Quality control and certification

-

Chemical and spectral analysis of materials

-

Mechanical testing

-

Metallography and structure control

-

Ultrasonic, magnetic particle and capillary flaw detection

-

Dimensional accuracy control on a 3D scanner

-

Quality control on a portable coordinate measuring machine

The availability of quality certificates and compliance with European and international standards is not just a formality, but a real tool to guarantee the safety, stability and trust in the products of the Western Foundry Group. We understand that quality is the basis for successful and long-term cooperation with our partners.

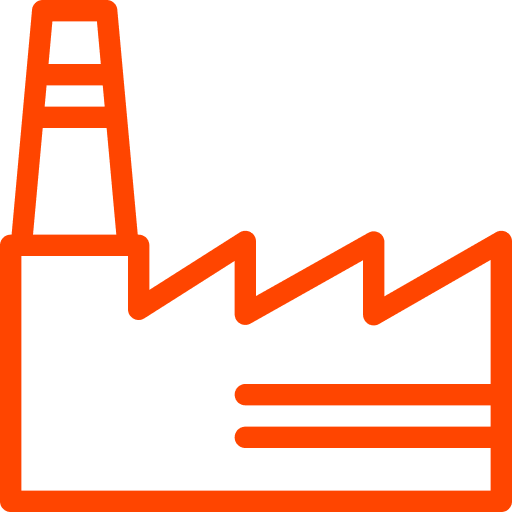

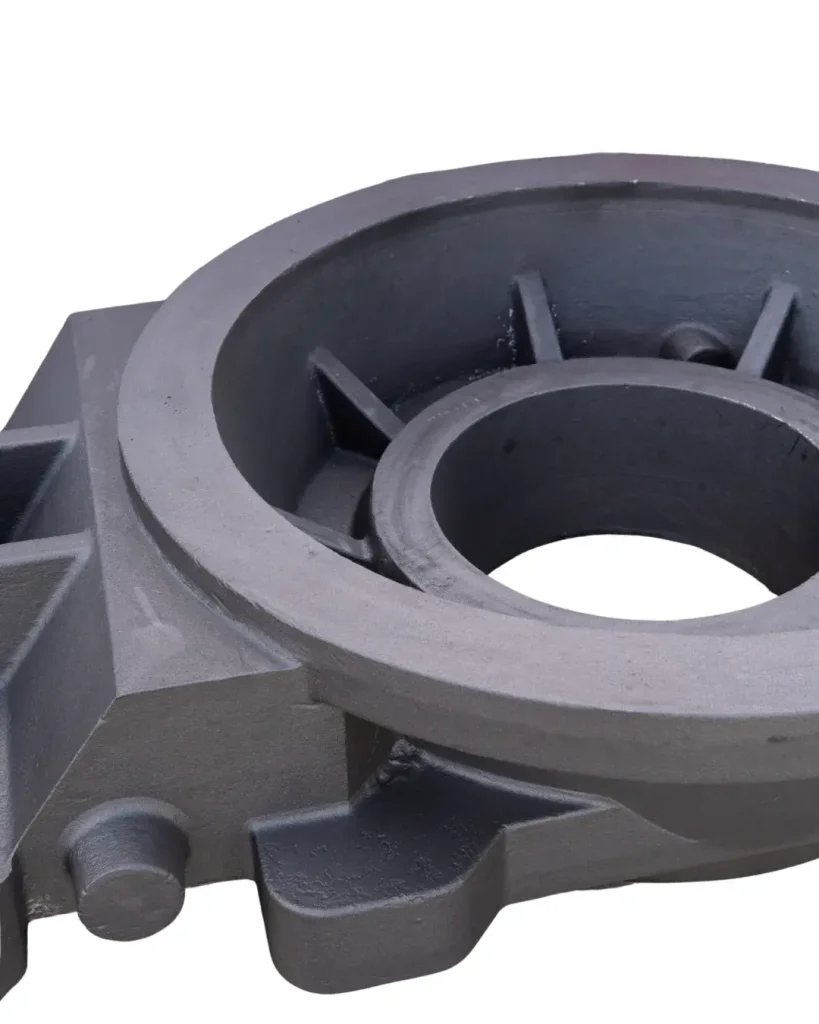

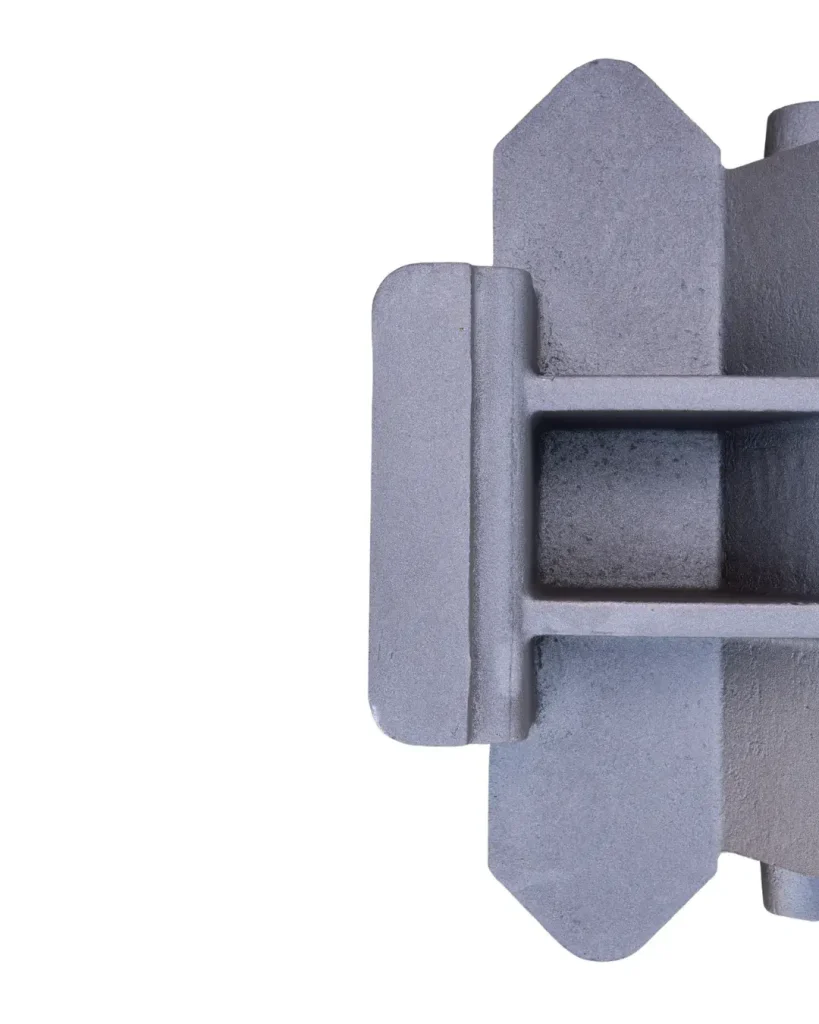

Examples of completed projects

Fill out the form to get a consultation